How Sand Blasting Machine Works? Blaster.co.in

Sandblasting is the procedure of advancing quality, abrasive material at excessive speeds to reap a couple of effects. it can be used to clean, deburr, take away paint and coatings, blast and / or in different ways to complete or improve the floor on many different materials.

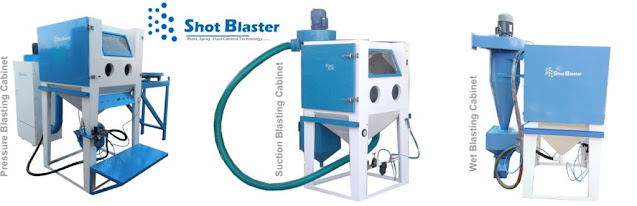

in terms of industrial professionals, the shot blast device

is the key device for shot blasting. Contractors, facility proprietors,

shipyards, rail yards, and different industrial and cellular applications

require, sand blasting machine or equipment

for cleansing, rust control, and surface preparation. these multipurpose

machines are powerful and require a certain degree of talent and protection

precautions to perform, however the mechanism of the machine is exceptionally

sincere to recognize.

For powerful sandblasting activity, it has end up vital to recognize

the sandblasting system and its working tactics. if you are a commercial

enterprise owner or your job profile is associated with sandblasting jobs, then

you definitely ought to examine this text. In this newsletter we're going to

cowl nearly every element related to sand

blasting equipment or system and its running approaches. but earlier than

persevering with, let me let you know a touch greater about it.

Sandblasting is also referred to as abrasive blasting. it's

far the operation of forcing a flow of abrasive fabric against a floor under

high pressure to smooth a tough floor, to shape a surface, or to do away with

contaminants from the surface. there are numerous versions of this procedure together

with shot blasting

machine, sand blasting machine, and grit blasting machine, and

so on.

How Sand Blasting Machine Works?

As soon as the media is loaded into the system, a sequence

of occasions must arise to provoke the blast. For one component, stress is

rather essential throughout this method. nothing will happen without precise

pressure.

to correctly pressurize the machine, you need a far off manage machine. these systems aren't most effective beneficial, they may be in reality an Micro Blaster required safety tool. pressing / miserable the manage lever will reason pressure / depression in the course of the machine.

For this purpose, the encapsulated remote manipulate gadget

is a pneumatically operated RLX manage manage, but electronic faraway controls

also are to be had (for use with blast hose lengths more than 100 ft).

The 2-line hoses are connected to each the inlet valve and

the control deal with. One hose video display units the air going to the

nozzle, while the alternative hose monitors the air going returned to the inlet

valve. when the manage handle isn't activated, air is launched at the base of

the deal with and no explosions can occur due to the fact the gadget isn't

pressurized.

however, for the most part, they function on this simplified

assumption: person-loaded media + pressurized air = blasting.

Abrasive blasting: Micro-abrasive

sand blasting presents a nice blast of abrasive to pin down a small location on

a small part or a big component the use of a small nozzle. Maximum usually, the

place to be blasted varies from about 1mm to just a few cm because abrasive

blasters with large nozzles are faster for large areas.

However, abrasive blasting system commonly consists of a manual nozzle, which directs a movement of abrasive particles. Consequently, the abrasive is blended with air in the mixing chamber to supply it to a nozzle wherein it's far subjected to a high speed air flow that propels it to paintings.

Sand blasting room -

Includes 3 of the four components of an blast cabin. Maximum blast rooms have

recycling systems ranging from manual recycling to fully reclaimed flooring

that supply the abrasive pneumatically or mechanically to a tool that cleans

the abrasive previous to recycling.

Comments

Post a Comment