Sand Blasting Machine India: Sand Blasting Machine for Sale

Sandblasting machines are designed to blast media such as aluminum oxide, glass beads, through a nozzle with compressed air supplied by an air compressor. Sandblasting machines are divided into gravity suction, direct pressure and blower types. A sand blasting machine is equipment used to clean mechanical service using silicon sand that operates under high pressure. The blast media is recalcitrant within the dust collector via suction force and separated from foreign matter as recalcitrant and detonated once again.

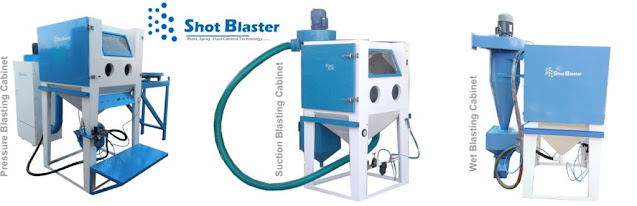

The dry method is environment friendly. As a Sand blasting Machine Manufacturer in India, customers get the most affordable Sandblasting Machines with highest quality standards meeting Indian and European Manufacturing Standards.Types of Sand Blasting Machine

There are mainly two types of sand blasting machine available in the market:-

· Cabinet Type Blasting Machine

· Portable Type Blasting Machine

Sand Blasting Machine: Working Structure

These days, it is rare to use real sand in abrasive blasting due to potential health, environmental and safety risks. Instead, abrasive powders known as blast media and finer objects such as copper slag, glass beads, aluminum oxide, and steel shot are used for sand blasting purposes. These fine abrasive media are extremely effective in cleaning, deburring, descaling, smoothing, polishing, and etching various metal surfaces on automotive components and construction equipment.

Essentially, sand blasting machine is the most economical and efficient way to prepare surfaces like metal by removing rust, dirt, or other deposits using just an air compressor. Compressed air provides fuel for sandblasting machines, allowing abrasive media to flow at high speed and hit the surface to remove rust or dirt or other deposits and contaminants.

The more pressure the sand blast produces, the faster the rate of impact of the blasting medium against the metal surface and the better cleaning can be achieved, but excessively strong sandblasting will damage a variety of materials.

Therefore, it is important to speak with a sand blasting machine manufacturer who can guide you on pressure levels and compressed air requirements.

Sand Blasting Machine: Components

· The nozzle allows the medium to be sprayed at a variable speed depending on the type of nozzle used.

· The blast container is basically the reservoir for the media and maintains the required pressure for blasting.

· Inlet and outlet valves control the air inlet and outlet and confirm whether there is pressure on the vessel.

· The pop-up valve responds to the pressure placed in the system and opens to exert pressure on the system.

· The mixture of air and abrasive can spray through the nozzle.

· The abrasive lure prevents the abrasive from traveling through the outlet valve.

· Once the media is loaded into the machine, a series of events must occur in order for the blasting to begin.

· The sand blasting machine valve controls the flow of abrasive from the blast bowl.

· Pressure is incredibly important throughout this method, and even if it's not the right pressure, nothing will happen and you'll be left with a rusty fender.

· The dual line hose area unit attached to each check valve and thus the handle.

· Once the administration handle is not activated, the air under the handle is free and there will be no explosion

· The abrasive media valve has 2 gaps and an outlet - one inlet is for the abrasive, the opposite is for the air, and therefore the outlet is for the air/abrasive mixture that will be conveyed through the blast hose.

Sand Blasting Machine: Uses

1. Despite the name, sand is not the only material that would be used in the "sandblasting" method. Depending on the media you're getting used to, a completely different abrasive is often used. These abrasives include: aluminum oxide, walnut shell, glass beads, etc.

2. On occasions, metal or plastic elements of equipment that need to be assembled have small burrs or various irregularities that alter the intended shape or are introduced into the media throughout the assembly. Sand blasting equipment is a good way to remove burrs, labels, and excess material.

3. One of the most common uses for sandblasting is to remove paint or rust. Sand blasting machine often remove paint, rust and various contaminants from the surface of cars, homes, machinery and almost any other surface area.

4. Sand blasting is one of the most economical methods of cleaning and preparing surfaces. Carpenters, machinists, automotive mechanics, and other industries will use sandblasting machines in their work, especially once they fully understand the different methods of sandblasting.

5. Sandblasting does not need to be forced to be used only on huge machines or buildings. It can also be adapted to clean kitchen tools. Screwdrivers, wrenches and various metal tools that have become dirty or rusty are cleaned up quickly and easily with a quick sand blasting equipments.

Sand Blasting Machine For Sale

BLASTER is the best industry in India that offer all type of sand blasting equipments at a reliable price. A sand blasting equipment is a sand blasting machine capable of smoothing rough surfaces, degreasing, removing rust, removing sand from cast iron parts, and cleaning pipes or tanks efficiently. This is a sand blasting machine for sale in India. It is the most economical means of cleaning old iron parts or removing rust from metal surfaces. Can be used for sand blasting, soda blasting, aluminum oxide blasting or walnut shelling.

Call: +91-9376271145 to get best price of sand blasting machine in India, sand blasting machine price without dust in India, sand blasting machine price, price of sand blasting machines.

Comments

Post a Comment